-

Products

-

Bi-Spectrum Thermal T-Camera

-

Big Bi-Spectrum Globular Therma

-

Infrared Thermal Camera Module-

-

Bi-Spectrum Cabin Thermal Camer

-

Yoseen Infrared Thermal Camera

-

Monocular Infrared Thermal Imag

-

UAV Load Thermal Camera

-

Bi-Spectrum Explosion-proof The

-

Professional Handheld Thermal C

-

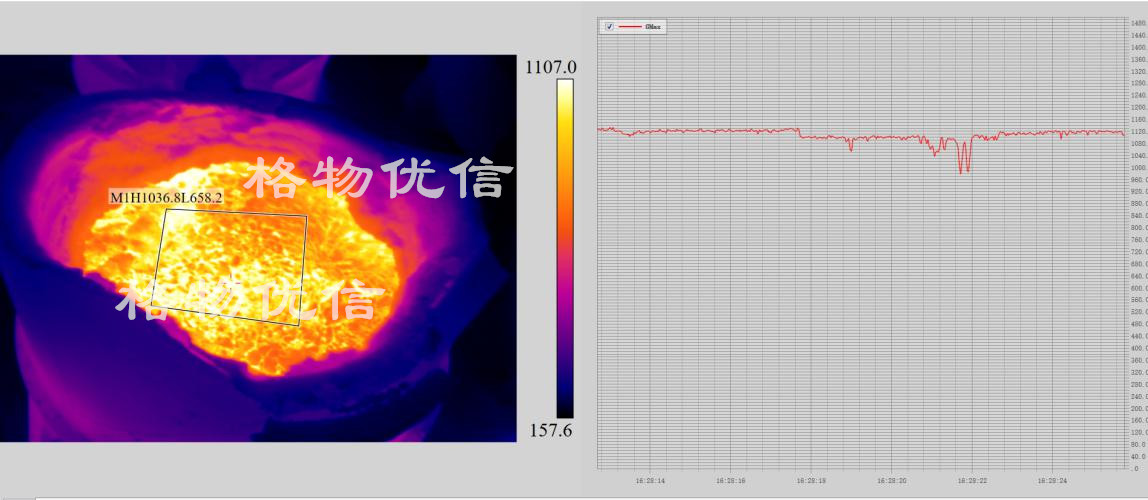

Blast Furnace Monitoring Therma

-

Bi-Spectrum Thermal Imaging Cam

-

Thermometric Cylinder Thermal C

-

-

Solutions

-

Thermal Imaging Explosion-Proof

-

Battery Workshop Infrared Therm

-

Iron Water Tank Infrared Therma

-

On-line Hot Air Furnace Thermal

-

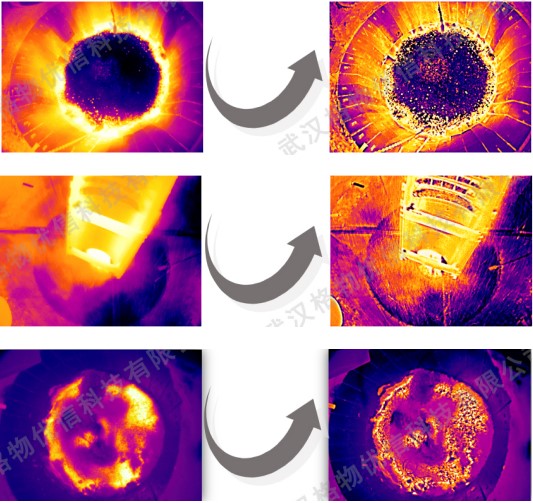

Furnace Charge Surface Monitori

-

On-line Infrared Thermal Imagin

-

Sintering Machine Thermal Imagi

-

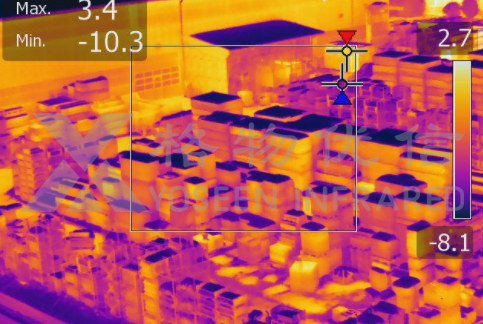

Thermal Temperature Monitoring

-

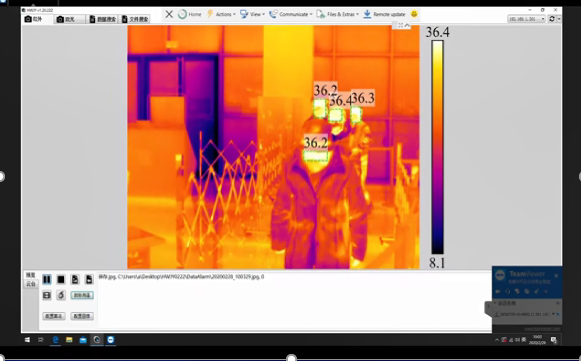

Infrared Thermal Imaging of Bod

-

Non-contact Infrared Solution f

-

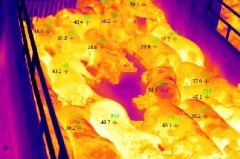

Thermal Camera Helps the Animal

-

Digital Forest Fire Prevention

-

- news

- about

- support

- contact

鄂公网安备 ******号

鄂公网安备 ******号