-

Products

-

Bi-Spectrum Thermal T-Camera

-

Big Bi-Spectrum Globular Therma

-

Infrared Thermal Camera Module-

-

Bi-Spectrum Cabin Thermal Camer

-

Yoseen Infrared Thermal Camera

-

Monocular Infrared Thermal Imag

-

UAV Load Thermal Camera

-

Bi-Spectrum Explosion-proof The

-

Professional Handheld Thermal C

-

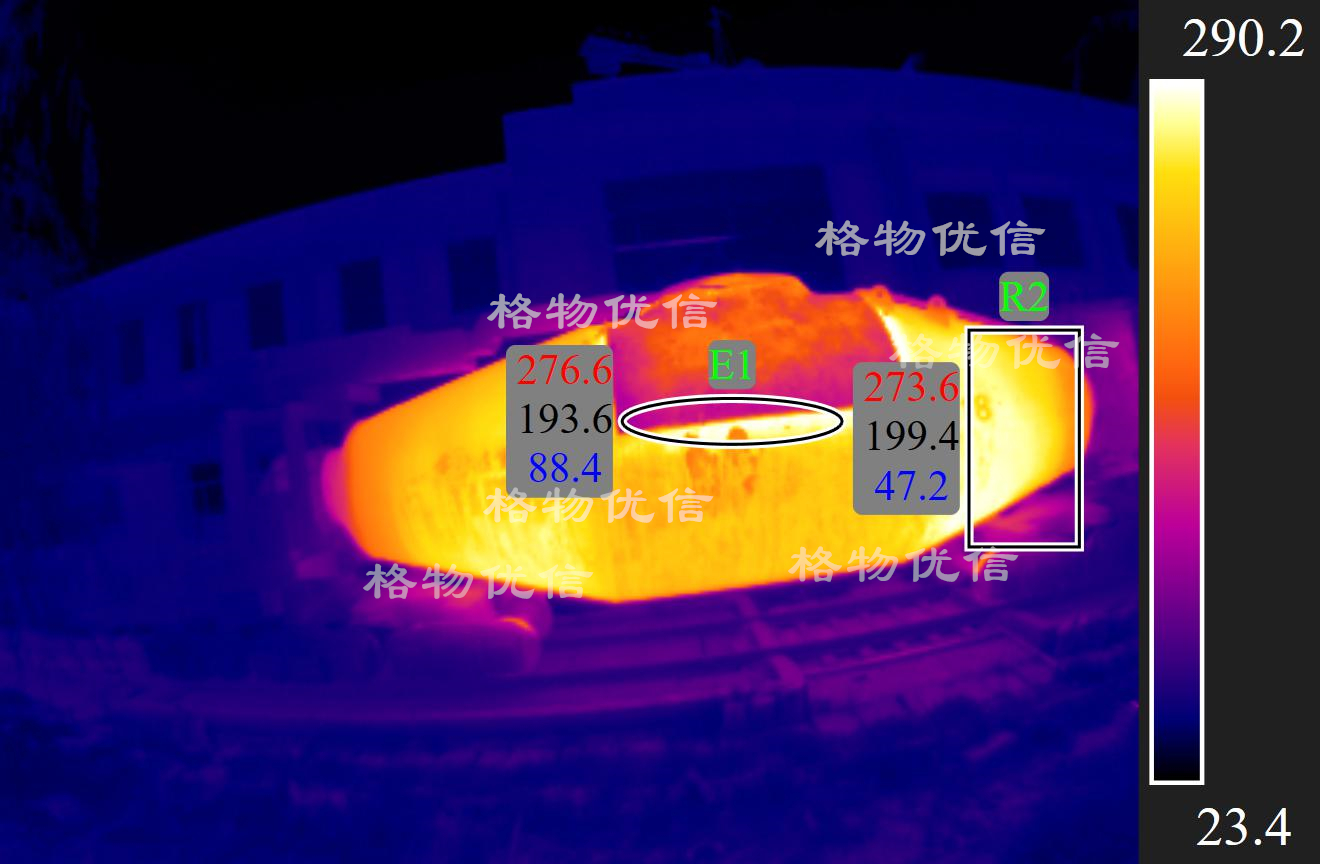

Blast Furnace Monitoring Therma

-

Bi-Spectrum Thermal Imaging Cam

-

Thermometric Cylinder Thermal C

-

-

Solutions

-

Temperature Detection of Torped

-

Blast Furnace Infrared Thermal

-

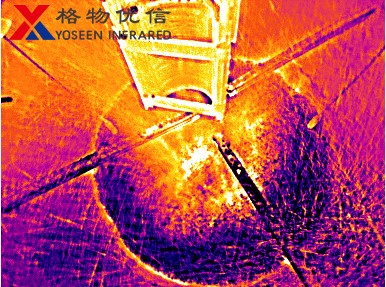

Thermal Imaging Coal Mining Ind

-

Electrolytic Aluminum Productio

-

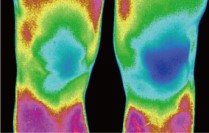

Infrared Thermal Imaging of Bod

-

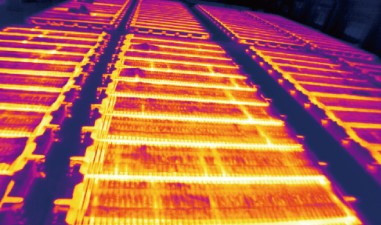

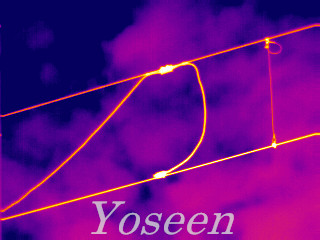

Automobile Rear Window Heating

-

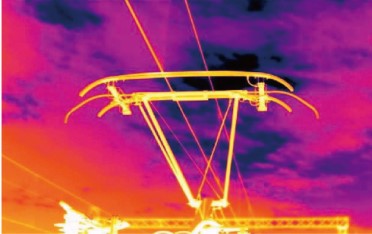

Railway Thermal Imaging Monitor

-

Ladle Temperature Monitoring Sy

-

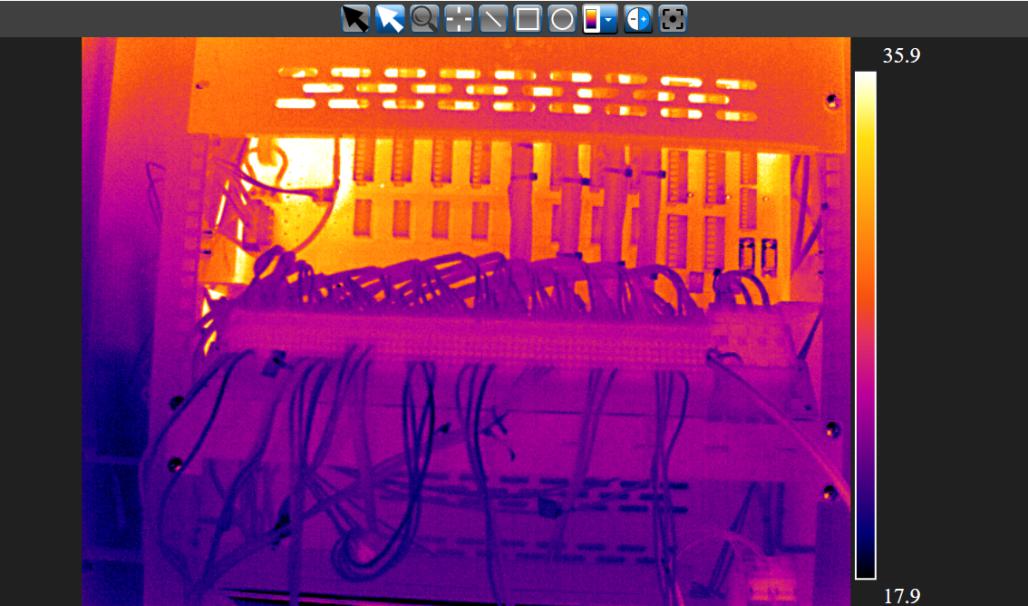

Power Distribution Cabinet Ther

-

On-line 24 Hour Hazardous Waste

-

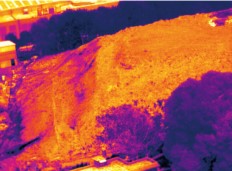

Digital Forest Fire Prevention

-

Infrared Thermal Camera Applied

-

- news

- about

- support

- contact

鄂公网安备 ******号

鄂公网安备 ******号