-

Products

-

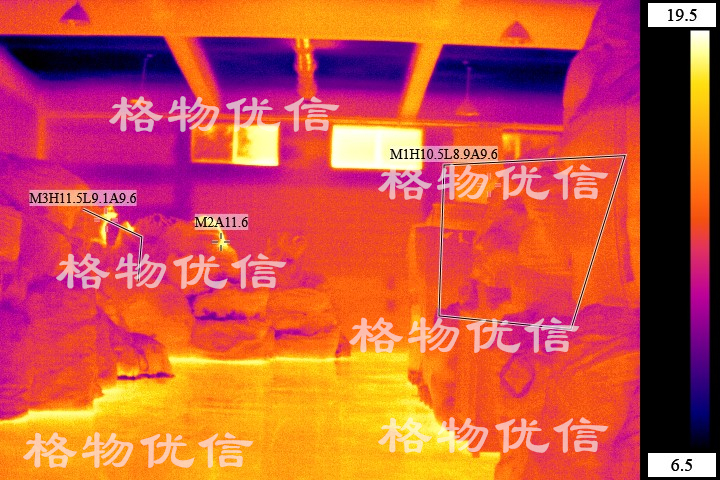

YOSEEN X384/X640H Thermal Came

-

Infrared Thermal Camera Module-

-

On-line Temperature Measuring T

-

Professional Handheld Thermal C

-

Bi-Spectrum Explosion-proof The

-

Small Bi-Spectrum Globular Ther

-

Big Bi-Spectrum Globular Therma

-

Monocular Explosion-proof Therm

-

Yoseen Infrared Thermal Camera

-

Bi-Spectrum Thermal T-Camera

-

Blast Furnace Monitoring Therma

-

Bi-Spectrum Cabin Thermal Camer

-

-

Solutions

-

The Application & Innovation of

-

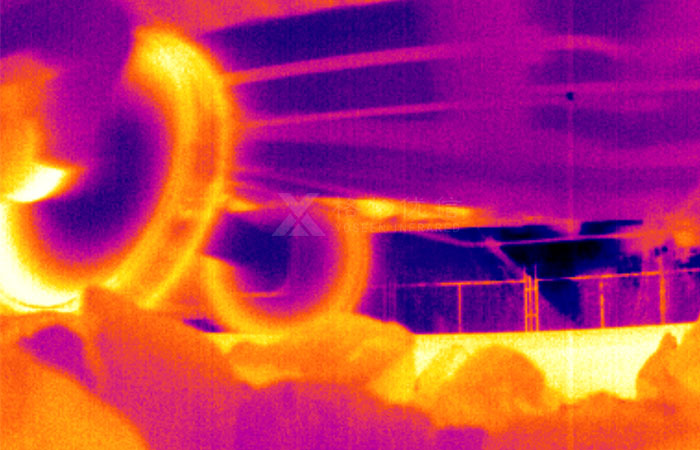

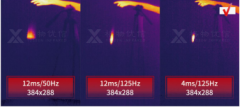

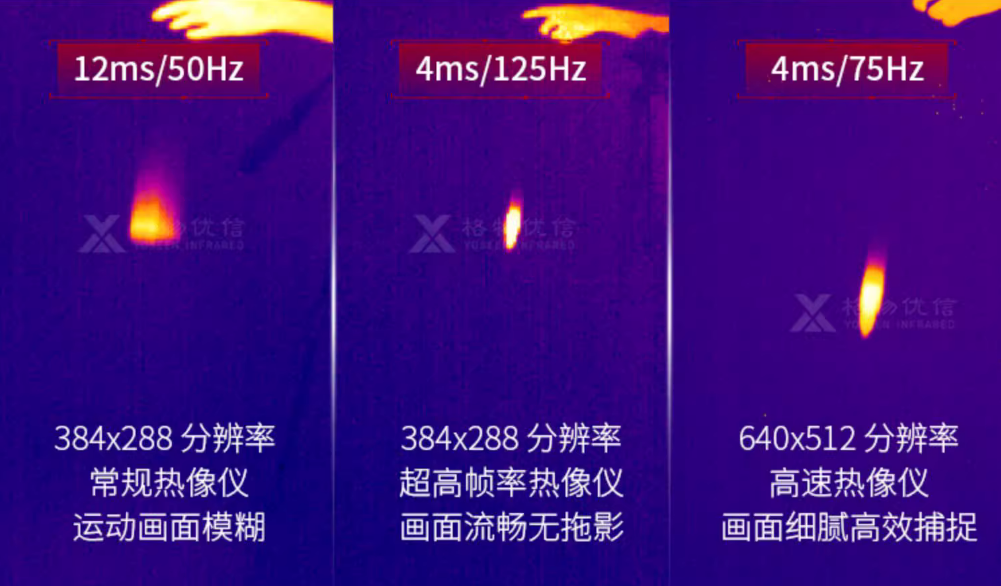

High-Speed Infrared Thermal Cam

-

High-Speed Thermal Cameras Cont

-

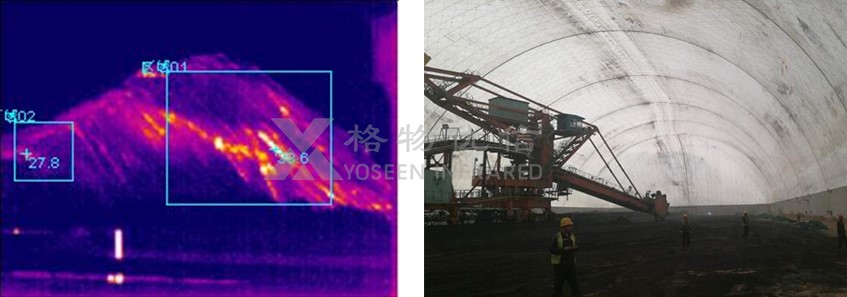

Prevention Solution of Coal Bun

-

Garbage Power Station Dump Pit

-

Transformer Substation Thermal

-

Converter Station Infrared Ther

-

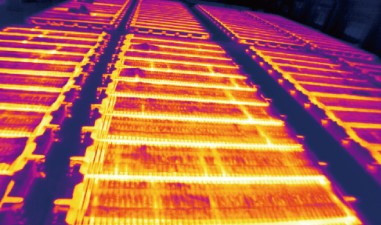

Electrolytic Aluminum Productio

-

Infrared Thermal Camera To Ensu

-

Infrared Thermal Camera Helps B

-

Factories Battery Warehouse The

-

Battery Warehouse Thermal Imagi

-

- news

- about

- support

- contact

鄂公网安备 ******号

鄂公网安备 ******号