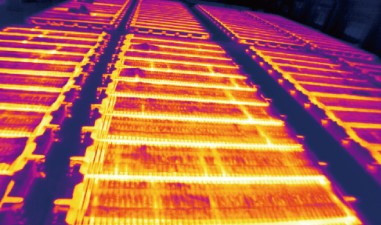

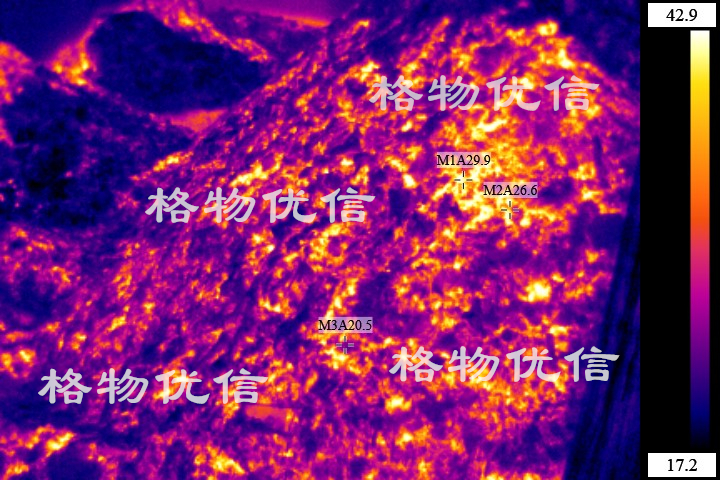

The coal industry is the pillar industry of the national economy, which plays a decisive role in the stability and development of the national economy and society. Following the coal fire early warning program of the previous period, this period mainly explains the application of the temperature monitoring function of infrared thermal imaging. In the coal system, it is very important to detect the running condition of the equipment or to prevent and control the safety. Infrared thermal camera has gradually become the main detection tool in coal system due to its characteristics of non-contact, full-image, rapid and accurate temperature measurement. With the continuous development of infrared technology, infrared thermal camera is more and more widely used in coal mine, which provides more advanced technical equipment for solving spontaneous combustion of coal seam and searching and rescuing miners. Because coal has a natural tendency of spontaneous combustion, spontaneous combustion often occurs in coal storage bunker. On the one hand, spontaneous combustion of coal releases poisonous and harmful gases and endangers the personal safety of workers. What is more serious is that the high-temperature coal in the transportation is easy to ignite the belt, which causes the whole coal conveying system to burn down and poses a serious threat to the normal and safe operation of the whole unit.

(1) Increase the ash content of coal, reduce the heat value, release toxic and harmful gases to endanger the personal safety of workers.

(2) The coal temperature in the spontaneous combustion state exceeds 350 degrees Celsius, which easily causes the coal ignition inside the whole coal shed.

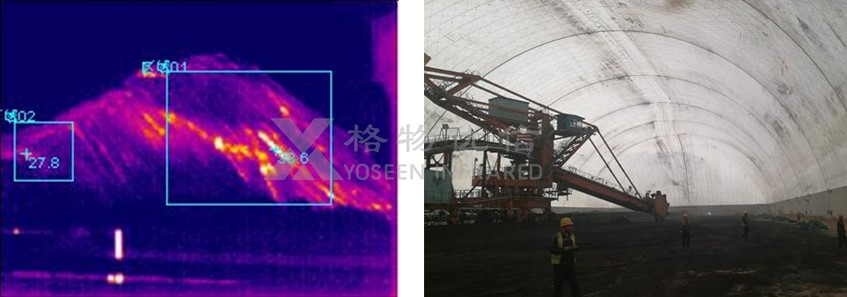

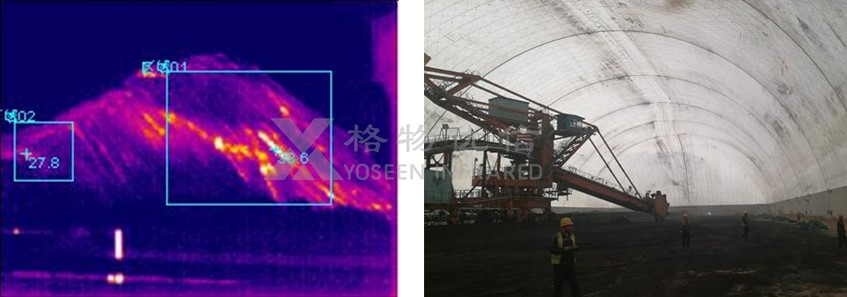

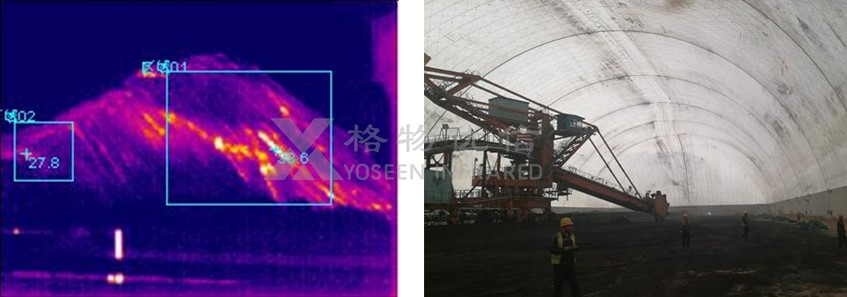

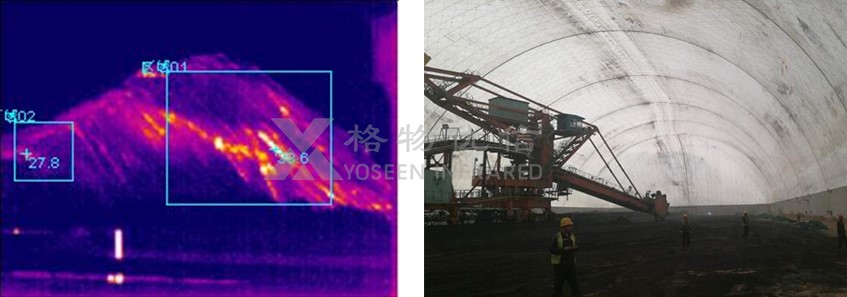

More serious is that the high temperature coal in transportation is extremely easy to ignite the belt, leading to the burning of the entire coal transport system, direct economic losses of tens of millions of yuan, and the unplanned shutdown of the generator set caused by the repair of the coal transport system, economic losses are more serious. It poses a serious threat to the normal and safe operation of the whole unit. More than 99% of coal piles are monitoring blind spots. Adopt thermocouple mode, theoretically 2 coal bunker should lay more than 800 thermocouple, installation is complex, wireless networking is not reliable, and the coal is constantly transported in and out, need someone to constantly plug and pull thermocouple, maintenance cost is unbearable, do not have practical value. The contact temperature measurement method has no practical value. Fire alarm intelligent thermal image real-time automatic scanning thermal distribution of coal, and generate the visual image, achieve real-time display 365 days * 24 hours hot distribution images, the user can according to the need of interest area to analyze the temperature, the highest temperature and automatically capture points, to find and automatic recognition of ignition, precise positioning of ignition, realize the early warning, help the personnel on duty quickly put out the fire. The non-contact monitoring method of intelligent thermal image does not affect coal loading and unloading operation. With the help of preset position scanning, the coal pile can be covered in all aspects without dead Angle, the spontaneous combustion point can be accurately located, the system is convenient for installation and networking, and the later maintenance free, with low operating cost.

Introduction of infrared thermal camera for coal mine

This M series intrinsically safe infrared thermal camera developed by Yoseen Infrared has been tested by Shanghai Institute of Quality technology and issued a report. It conforms to the standards of National Coal Mine Safety Administration and is an intrinsically safe infrared thermal camera for mine use. The product is undergoing the certification of intrinsically safe and coal safety, and the explosion-proof protection standard IP54. M series intrinsically safe infrared thermal camera housing uses reinforced ABS engineering plastic, the weight is only about 100g, convenient and compact. In addition, the product can automatically add multiple or a single hot spot tracking to the monitored object. Once the temperature exceeds the threshold value detected, the fire protection system will be connected immediately and alarm signal will be started, thus avoiding the occurrence of safety accidents to a great extent. Depends on the other hand, optimal letter explosion-proof type thermal camera (with explosion-proof certificate: ExdICT6Gb/ExtDA21IP68T80 ° C) temperature measurement accuracy, performance is remarkable, applicable to factories with IA, IB, IC T1 ~ T6 group of combustible gas, steam and air to form explosive mixture of 0, 1 zone and 2 zone places as well as the formation of combustible dust in mixture with air of 20, 21, 22 area explosive dangerous location.

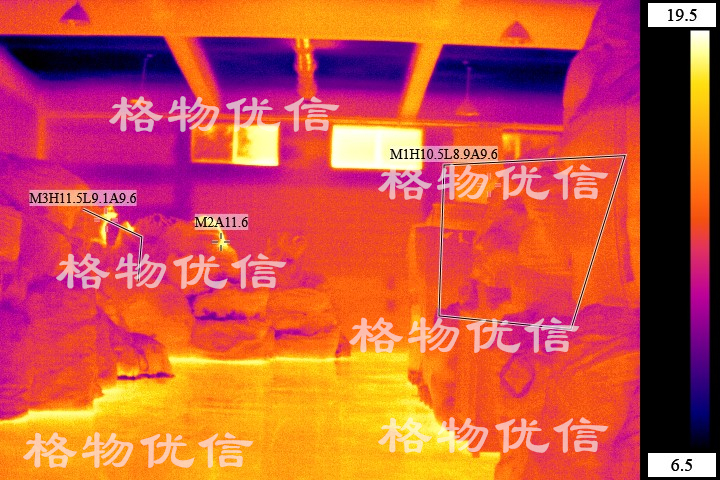

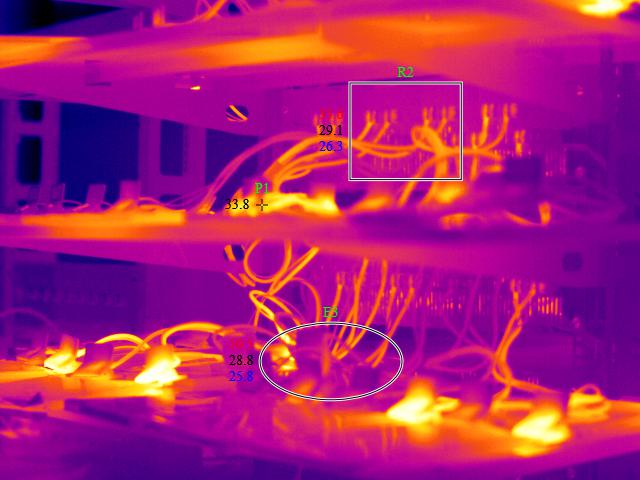

The specific application scope of infrared thermal camera used in this coal mine includes inspecting the distribution and location of hidden fire sources. Check the permeable water of roof and mining area; Check all kinds of electrical and power equipment accident hidden danger; Misfire. To seek help in a mine accident; The infrared thermal camera can observe the heat in the field of view in the mine, coal pile, coal and pulverized coal transmission and other places where ground gangue ignition occurs, even under bad conditions. It is quick to use without contact.

The coal industry is the pillar industry of the national economy, which plays a decisive role in the stability and development of the national economy and society. Following the coal fire early warning program of the previous period, this period mainly explains the application of the temperature monitoring function of infrared thermal imaging. In the coal system, it is very important to detect the running condition of the equipment or to prevent and control the safety. Infrared thermal camera has gradually become the main detection tool in coal system due to its characteristics of non-contact, full-image, rapid and accurate temperature measurement. With the continuous development of infrared technology, infrared thermal camera is more and more widely used in coal mine, which provides more advanced technical equipment for solving spontaneous combustion of coal seam and searching and rescuing miners. Because coal has a natural tendency of spontaneous combustion, spontaneous combustion often occurs in coal storage bunker. On the one hand, spontaneous combustion of coal releases poisonous and harmful gases and endangers the personal safety of workers. What is more serious is that the high-temperature coal in the transportation is easy to ignite the belt, which causes the whole coal conveying system to burn down and poses a serious threat to the normal and safe operation of the whole unit.

(1) Increase the ash content of coal, reduce the heat value, release toxic and harmful gases to endanger the personal safety of workers.

(2) The coal temperature in the spontaneous combustion state exceeds 350 degrees Celsius, which easily causes the coal ignition inside the whole coal shed.

More serious is that the high temperature coal in transportation is extremely easy to ignite the belt, leading to the burning of the entire coal transport system, direct economic losses of tens of millions of yuan, and the unplanned shutdown of the generator set caused by the repair of the coal transport system, economic losses are more serious. It poses a serious threat to the normal and safe operation of the whole unit. More than 99% of coal piles are monitoring blind spots. Adopt thermocouple mode, theoretically 2 coal bunker should lay more than 800 thermocouple, installation is complex, wireless networking is not reliable, and the coal is constantly transported in and out, need someone to constantly plug and pull thermocouple, maintenance cost is unbearable, do not have practical value. The contact temperature measurement method has no practical value. Fire alarm intelligent thermal image real-time automatic scanning thermal distribution of coal, and generate the visual image, achieve real-time display 365 days * 24 hours hot distribution images, the user can according to the need of interest area to analyze the temperature, the highest temperature and automatically capture points, to find and automatic recognition of ignition, precise positioning of ignition, realize the early warning, help the personnel on duty quickly put out the fire. The non-contact monitoring method of intelligent thermal image does not affect coal loading and unloading operation. With the help of preset position scanning, the coal pile can be covered in all aspects without dead Angle, the spontaneous combustion point can be accurately located, the system is convenient for installation and networking, and the later maintenance free, with low operating cost.

Introduction of infrared thermal camera for coal mine

This M series intrinsically safe infrared thermal camera developed by Yoseen Infrared has been tested by Shanghai Institute of Quality technology and issued a report. It conforms to the standards of National Coal Mine Safety Administration and is an intrinsically safe infrared thermal camera for mine use. The product is undergoing the certification of intrinsically safe and coal safety, and the explosion-proof protection standard IP54. M series intrinsically safe infrared thermal camera housing uses reinforced ABS engineering plastic, the weight is only about 100g, convenient and compact. In addition, the product can automatically add multiple or a single hot spot tracking to the monitored object. Once the temperature exceeds the threshold value detected, the fire protection system will be connected immediately and alarm signal will be started, thus avoiding the occurrence of safety accidents to a great extent. Depends on the other hand, optimal letter explosion-proof type thermal camera (with explosion-proof certificate: ExdICT6Gb/ExtDA21IP68T80 ° C) temperature measurement accuracy, performance is remarkable, applicable to factories with IA, IB, IC T1 ~ T6 group of combustible gas, steam and air to form explosive mixture of 0, 1 zone and 2 zone places as well as the formation of combustible dust in mixture with air of 20, 21, 22 area explosive dangerous location.

The specific application scope of infrared thermal camera used in this coal mine includes inspecting the distribution and location of hidden fire sources. Check the permeable water of roof and mining area; Check all kinds of electrical and power equipment accident hidden danger; Misfire. To seek help in a mine accident; The infrared thermal camera can observe the heat in the field of view in the mine, coal pile, coal and pulverized coal transmission and other places where ground gangue ignition occurs, even under bad conditions. It is quick to use without contact.

The coal industry is the pillar industry of the national economy, which plays a decisive role in the stability and development of the national economy and society. Following the coal fire early warning program of the previous period, this period mainly explains the application of the temperature monitoring function of infrared thermal imaging. In the coal system, it is very important to detect the running condition of the equipment or to prevent and control the safety. Infrared thermal camera has gradually become the main detection tool in coal system due to its characteristics of non-contact, full-image, rapid and accurate temperature measurement. With the continuous development of infrared technology, infrared thermal camera is more and more widely used in coal mine, which provides more advanced technical equipment for solving spontaneous combustion of coal seam and searching and rescuing miners. Because coal has a natural tendency of spontaneous combustion, spontaneous combustion often occurs in coal storage bunker. On the one hand, spontaneous combustion of coal releases poisonous and harmful gases and endangers the personal safety of workers. What is more serious is that the high-temperature coal in the transportation is easy to ignite the belt, which causes the whole coal conveying system to burn down and poses a serious threat to the normal and safe operation of the whole unit.

(1) Increase the ash content of coal, reduce the heat value, release toxic and harmful gases to endanger the personal safety of workers.

(2) The coal temperature in the spontaneous combustion state exceeds 350 degrees Celsius, which easily causes the coal ignition inside the whole coal shed.

More serious is that the high temperature coal in transportation is extremely easy to ignite the belt, leading to the burning of the entire coal transport system, direct economic losses of tens of millions of yuan, and the unplanned shutdown of the generator set caused by the repair of the coal transport system, economic losses are more serious. It poses a serious threat to the normal and safe operation of the whole unit. More than 99% of coal piles are monitoring blind spots. Adopt thermocouple mode, theoretically 2 coal bunker should lay more than 800 thermocouple, installation is complex, wireless networking is not reliable, and the coal is constantly transported in and out, need someone to constantly plug and pull thermocouple, maintenance cost is unbearable, do not have practical value. The contact temperature measurement method has no practical value. Fire alarm intelligent thermal image real-time automatic scanning thermal distribution of coal, and generate the visual image, achieve real-time display 365 days * 24 hours hot distribution images, the user can according to the need of interest area to analyze the temperature, the highest temperature and automatically capture points, to find and automatic recognition of ignition, precise positioning of ignition, realize the early warning, help the personnel on duty quickly put out the fire. The non-contact monitoring method of intelligent thermal image does not affect coal loading and unloading operation. With the help of preset position scanning, the coal pile can be covered in all aspects without dead Angle, the spontaneous combustion point can be accurately located, the system is convenient for installation and networking, and the later maintenance free, with low operating cost.

Introduction of infrared thermal camera for coal mine

This M series intrinsically safe infrared thermal camera developed by Yoseen Infrared has been tested by Shanghai Institute of Quality technology and issued a report. It conforms to the standards of National Coal Mine Safety Administration and is an intrinsically safe infrared thermal camera for mine use. The product is undergoing the certification of intrinsically safe and coal safety, and the explosion-proof protection standard IP54. M series intrinsically safe infrared thermal camera housing uses reinforced ABS engineering plastic, the weight is only about 100g, convenient and compact. In addition, the product can automatically add multiple or a single hot spot tracking to the monitored object. Once the temperature exceeds the threshold value detected, the fire protection system will be connected immediately and alarm signal will be started, thus avoiding the occurrence of safety accidents to a great extent. Depends on the other hand, optimal letter explosion-proof type thermal camera (with explosion-proof certificate: ExdICT6Gb/ExtDA21IP68T80 ° C) temperature measurement accuracy, performance is remarkable, applicable to factories with IA, IB, IC T1 ~ T6 group of combustible gas, steam and air to form explosive mixture of 0, 1 zone and 2 zone places as well as the formation of combustible dust in mixture with air of 20, 21, 22 area explosive dangerous location.

The specific application scope of infrared thermal camera used in this coal mine includes inspecting the distribution and location of hidden fire sources. Check the permeable water of roof and mining area; Check all kinds of electrical and power equipment accident hidden danger; Misfire. To seek help in a mine accident; The infrared thermal camera can observe the heat in the field of view in the mine, coal pile, coal and pulverized coal transmission and other places where ground gangue ignition occurs, even under bad conditions. It is quick to use without contact.

鄂公网安备 ******号

鄂公网安备 ******号