1. Project background

High-pressure pump to draw water, liquid (solution), the outlet pressure, the biggest pressure up to 11 kg), suitable for the need for liquid spray, spraying, washing, irrigation, shower, transfer, promotion, cleaning and so on many kinds of occasions, widely used in water treatment, liquid sampling, scientific research, instrumentation, chemical analysis, medical care, medicine and health care, biological engineering, automatic control, environmental protection and other fields. When the high-pressure pump works for a long time, the motor, bearing and so on are prone to temperature rise, and there will be hidden trouble in the long run. Therefore, real-time temperature detection of high pressure pump is very important.

2. Project overview

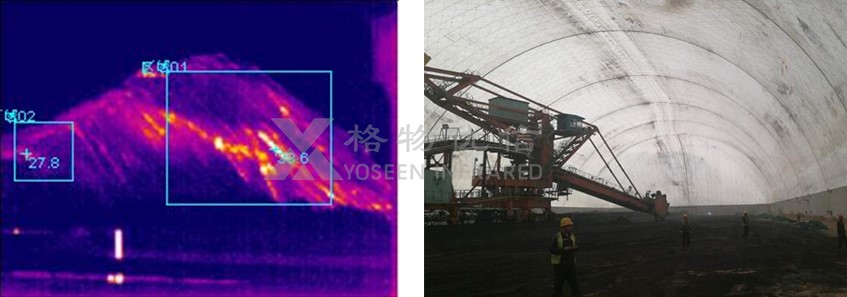

This project requires the installation of 4 infrared thermal cameras, distributed in 4 different directions, 360° comprehensive monitoring.

Because conventional video surveillance system monitoring effect is poor, can't at night to temperature limitations such as high pressure pump, need to use the advanced monitoring technology, the realization of the whole regional all-weather overall monitoring of the high pressure pump, in order to reduce the personnel on duty working strength, improve the work efficiency, and provide effective means for monitoring for the personnel on duty. According to safety management requirements, the following requirements should be met:

Risk early warning and fire alarm: real-time panoramic monitoring and high sensitivity feature, can realize rapid alarm to high temperature;

Non-contact temperature measurement, does not affect the normal operation of high pressure pump;

Alarm log: Alarm record and image synchronous storage system;

Video images of all collection points can be stored in the whole process or triggered by alarm, and the previous historical images can be queried and played back.

Power supply in all-weather environment, to ensure that the system uninterrupted power supply.

3. System overview

3.1 Overall system architecture design

On-line monitoring system of high pressure pump is composed of network transmission system, video data storage system, remote monitoring management system, monitoring center display system, etc. The monitoring center can monitor and manage the front end remotely. At the same time, image monitoring and analysis and automatic alarm recognition can be realized, and data acquisition, analysis, high temperature point positioning, automatic alarm and other functions of intelligent monitoring of high pressure pump can be realized through digital transmission network.

3.2 System composition

The on-line monitoring system of high pressure pump is mainly composed of monitoring center, transmission link system and front-end infrared monitoring equipment.

The front monitoring point of the on-line monitoring system of the high pressure pump is an on-line infrared thermal camera. The monitoring point transmits the data to the monitoring center through the network for infrared temperature measurement, image intelligent analysis, storage and other auxiliary decisions.

Data transmission link includes optical fiber, computer network and other forms. The specific transmission link can be configured according to the actual situation on the project site.

4. Design of on-line monitoring system for high pressure pump

4.1 Monitoring system

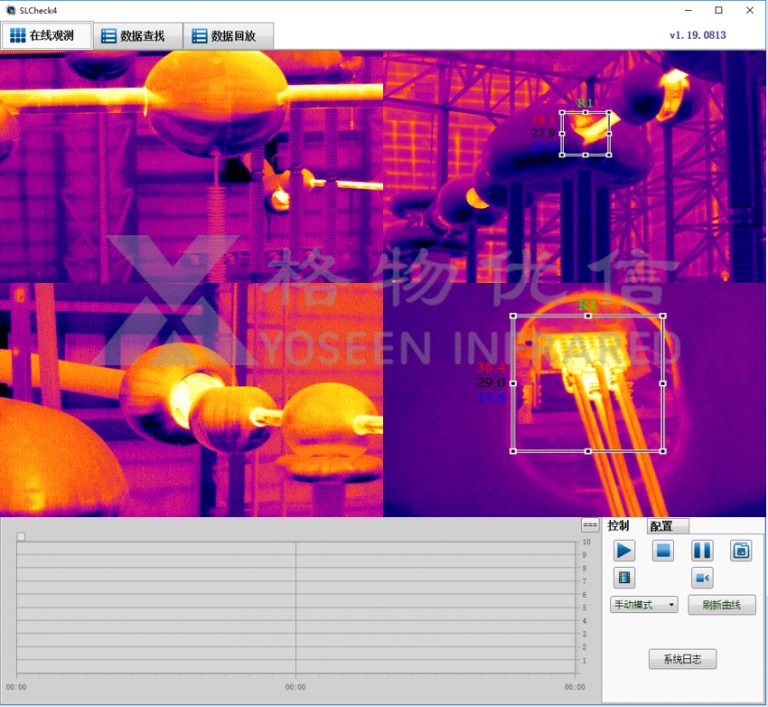

Monitoring center mainly consists of software, which is an organization of system function and management. Since the video signal and control signal have all been connected to Ethernet, any computer in Ethernet can be monitored by means of permission control.

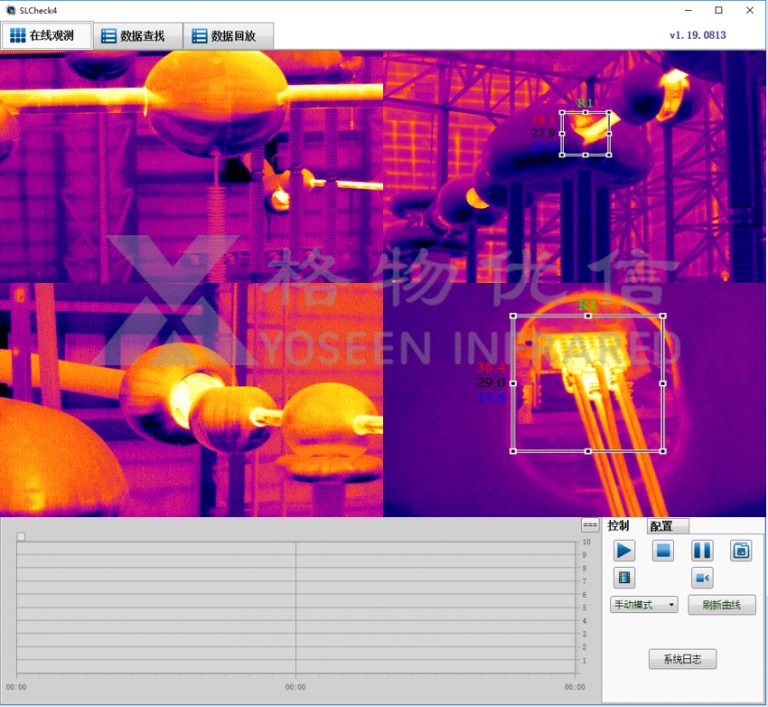

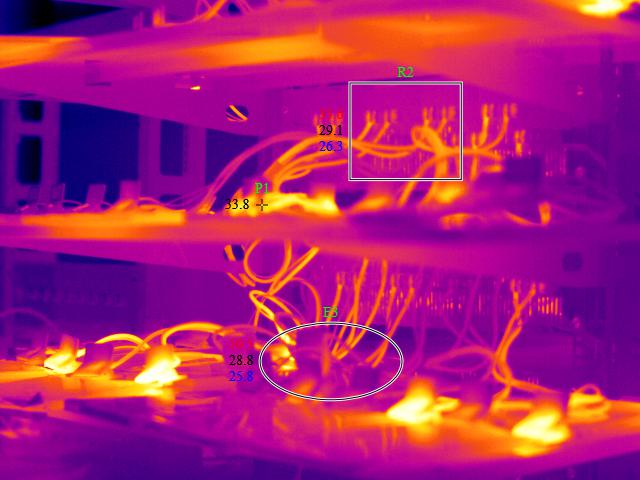

4.1.1 Real-time monitoring

➢ area between the monitoring center and the front-end monitoring system of the remote infrared image real-time transmission of low bandwidth, while ensuring real-time and image quality under the premise of system USES new technologies to reduce the bandwidth resource utilization.

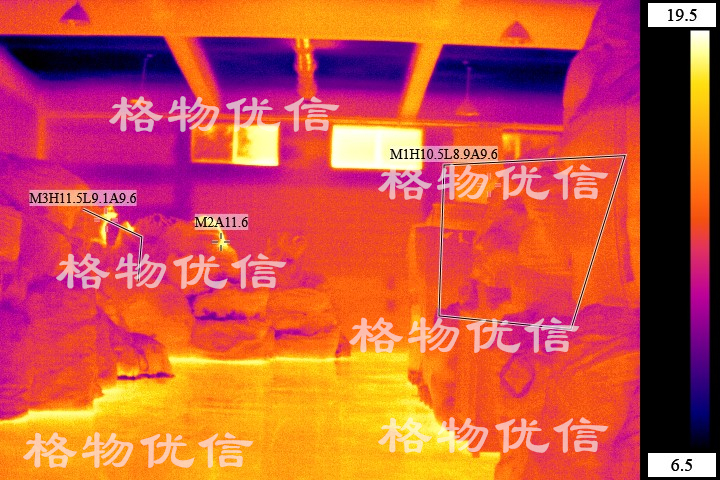

➢ in the monitoring center can be real-time monitoring all image information of each point temperature, the temperature real-time monitoring information, complete remote infrared image real-time display, monitor, storage, analysis, report processing, etc.

➢ in the monitoring center can be real-time monitoring multichannel infrared image information and realize one machine with screen monitor at the same time; Monitoring center and multiple terminals can simultaneously monitor any monitoring point.

4.1.2 Remote monitoring

➢ remote control infrared monitoring equipment.

➢ remote infrared alarm parameters, such as monitoring, alarm temperature, alarm, temperature alarm and so on.

➢ according to alarm signal switch location specified infrared thermal image instrument, realize the alarm linkage.

➢ receiving alarm information of the monitoring system, infrared thermal image instrument and specify the corresponding video, in case of accident investigation.

➢ all alarm messages are automatically saved, when necessary, can print output.

➢ according to preset report format, automatically generated report processing.

➢ the monitoring center can display, store the monitoring points of the infrared thermal camera real-time image.

➢ the monitoring center can remote playback stand on any historical images of infrared thermal camera (time can be set).

➢ system has strong fault tolerance, not caused by wrong operation of system error and collapse.

➢ system has to stand side equipment remote configuration, remote maintenance, the ability to remotely start.

➢ office computer system can be used online as a share of the workstation (with appropriate software).

4.2 System Software

l real-time display, real-time display total radiation heat, the temperature of the attendant can look at any position, recording and take photos, analysis was carried out on the abnormal situation, and issue a professional test report.

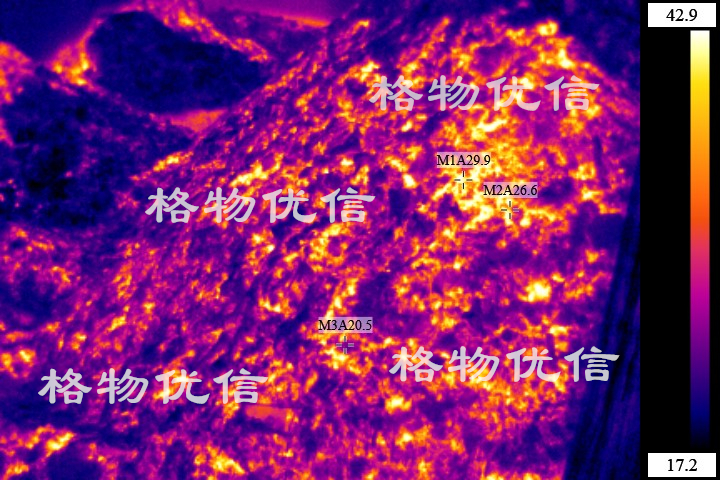

l temperature tracking: automatic like figure the whole picture of heat or temperature rise trend analysis on a particular area, early found hidden danger area.

l data capture: time thermal imaging image data, convenient for later analysis.

l high temperature trigger shooting and alarm: when there is a temperature anomaly, monitoring the background can be found in time, trigger the alarm, sound and light alarm module will send alarm and software background will take pictures in the process of the incident.

l fault self-diagnosis: when terminal equipment malfunction, system can remind the personnel on duty.

l custom alarm threshold and level: system can be defined in four different alarm threshold and level, to assist the staff degree of hidden danger in the event of an emergency and the development trend to assess.

l automatic classification storage: monitoring data, abnormal data and alarm information is automatically stored in the corresponding equipment data, fast and accurate analysis of the call.

l reporting features: according to customer request custom all kinds of report, and can be exported as Word format.

l temperature curve: software observable object temperature real-time temperature curve, thereby to trend judgement.

5. System characteristics

The high pressure pump on-line monitoring system can detect the temperature situation in real time and send the sound and light alarm signal according to the pre-set warning value, so that the personnel on duty can take corresponding measures in time to ensure the normal work of the high pressure pump. It has the following advantages:

1. Do not affect the work, maintenance free: non-contact temperature measurement, do not affect the normal operation of the high-pressure pump.

2. Alarm visualization: infrared thermal image is provided so that the personnel on duty can quickly locate the alarm position and deal with it.

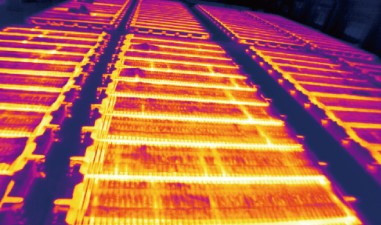

3. Automatic monitoring of high-resolution infrared thermal image: realize full coverage and all-weather monitoring of high-pressure pumps.

4. Simultaneous monitoring of multiple devices: Industry software can simultaneously monitor multiple devices, with a simple and intuitive screen.

5. Intelligent analysis and alarm: Through the acquired temperature data, the system can intelligently analyze the current state and issue an alarm.

6. Automatic equipment identification management: The heat map collected by the system (whether automatic or manual) is automatically identified. The effective equipment target of the heat map can be identified through the image registration method to ensure the effectiveness of temperature detection.

7. Detailed equipment working status management: Establish a management system for all equipment and equipment components, so that specific hidden dangers (fever) can be identified in detail when the alarm occurs.

8. Automatic warning: In the monitoring process, if abnormal temperature of the target device is found, it will automatically alarm. The alarm information includes text information and sound information, which will remind the operator of the specific alarm position information, so as to track the hot spots, confirm the alarm situation and troubleshoot the problem.

9. High detection accuracy: The sampling accuracy of the infrared thermal camera adopted is higher than that of the portable instrument in terms of precision and resolution, which is convenient for timely judging the specific hot spots of the equipment, thus gaining precious time for accurate judging and taking corresponding measures.

10. The system has the advantages of high reliability and real-time performance: using this system, the natural environment will not have any impact, no matter wind and rain, or low temperature and high temperature can realize uninterrupted automatic monitoring.

11. Manpower saving: This system can realize automatic inspection, automatic warning, automatic output report and other functions of the equipment due to its high degree of automation. The frequency of personnel visiting the site was reduced, and the work efficiency of personnel on duty was improved.

鄂公网安备 ******号

鄂公网安备 ******号